Creative Aspects of Matching Veneers

Veneer is a solid, genuine wood, just as it grows in the tree. It can be laminated to a substraight (for example particle board, masonite, plywood). This can be done in many fashions creating different looks.

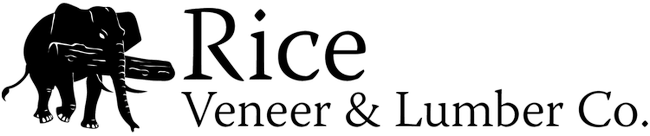

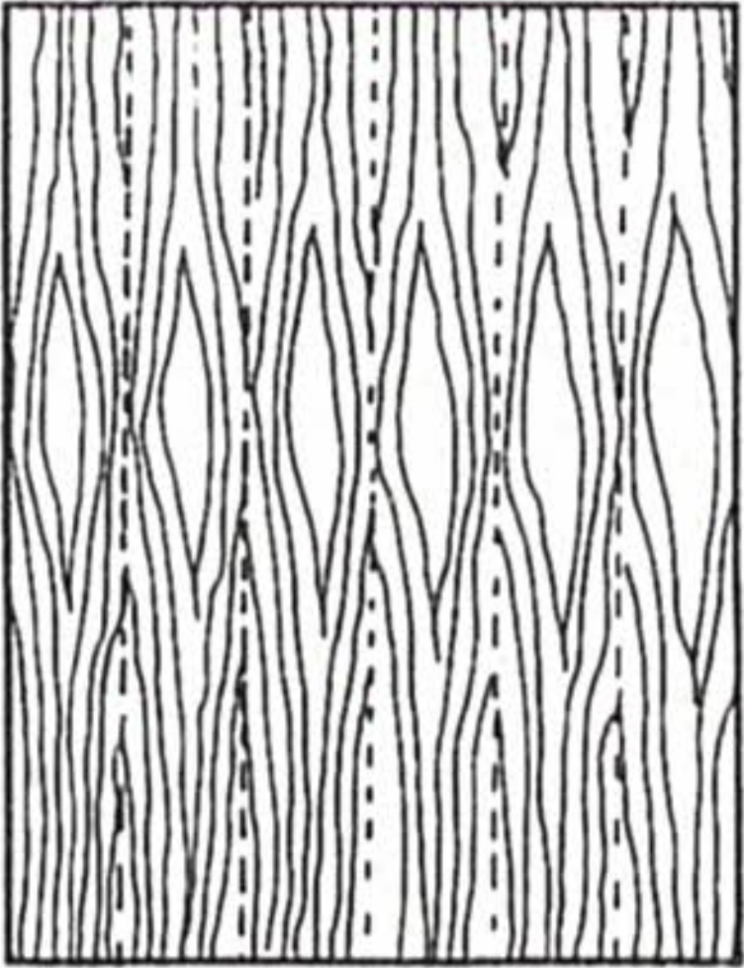

Book Match

Book matching is achieved when successive veneer leaves in a flitch are turned over like the pages in a book and are glued in this manner. Since the reverse side of one leaf is a mirror image of the succeeding leaf, the result is a series of pairs.

Individual panels can be matched this way, or you can achieve this look over manny panels by sequence matching the panels.

Book matching is the most common match.

This may yield color variations in some species which may be minimized by proper finishing techniques.

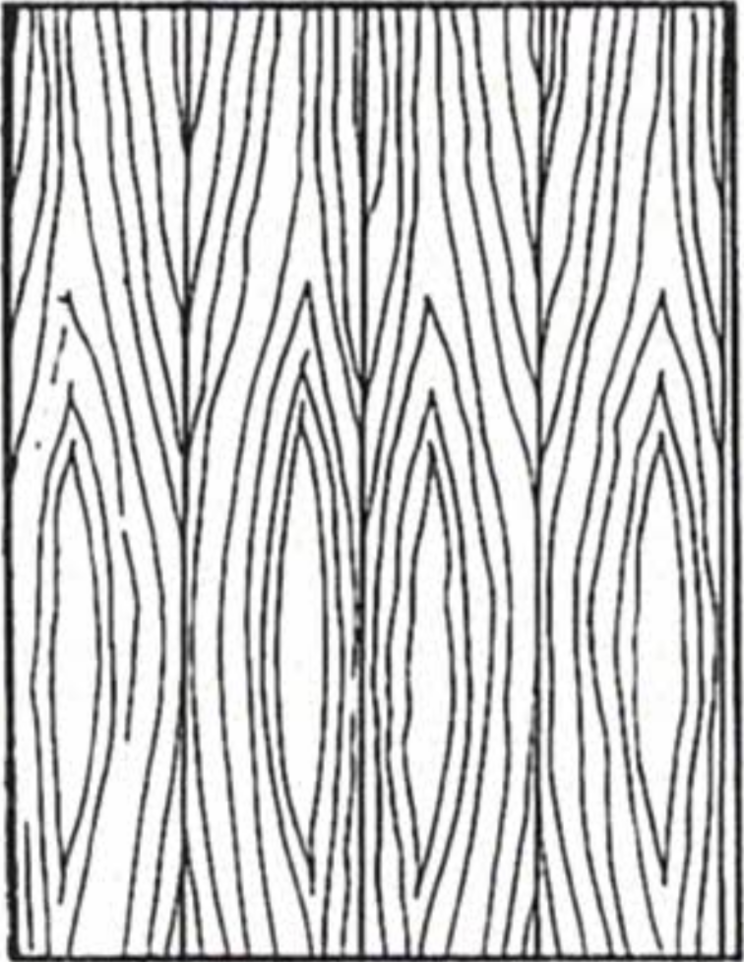

Butt Match

Butt matching is achieved when veneers are matched as described for book matching but the ends of the sheets are also matched. At times, the veneer being used are not long enough to cover the desired panel heights. In this case the veneer leaves can also be flipped end for end and the ends matched.

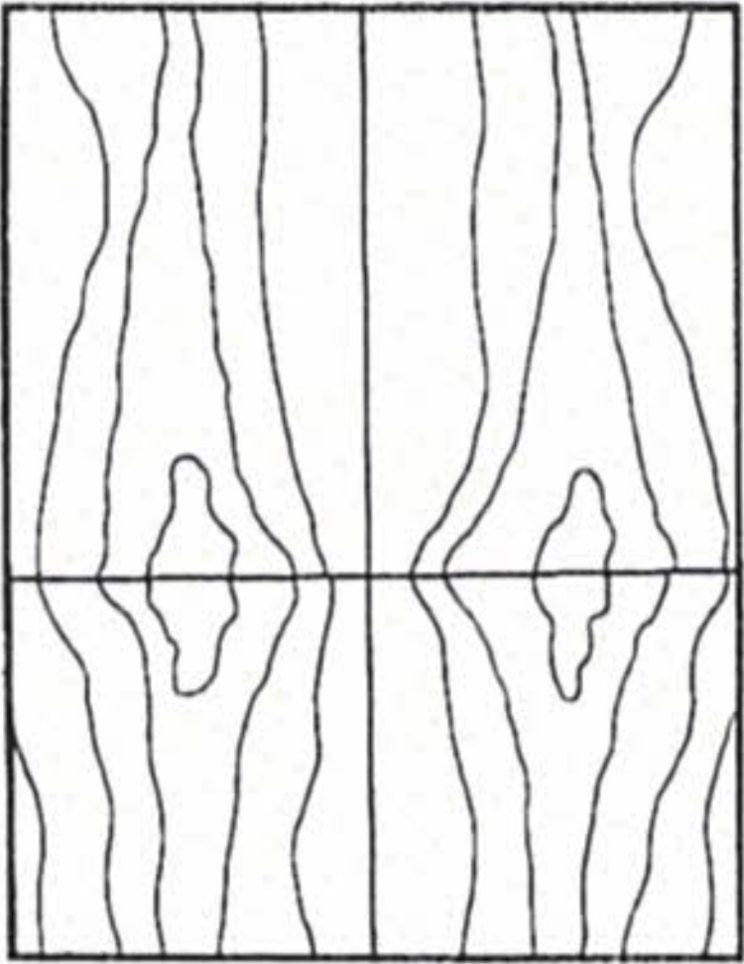

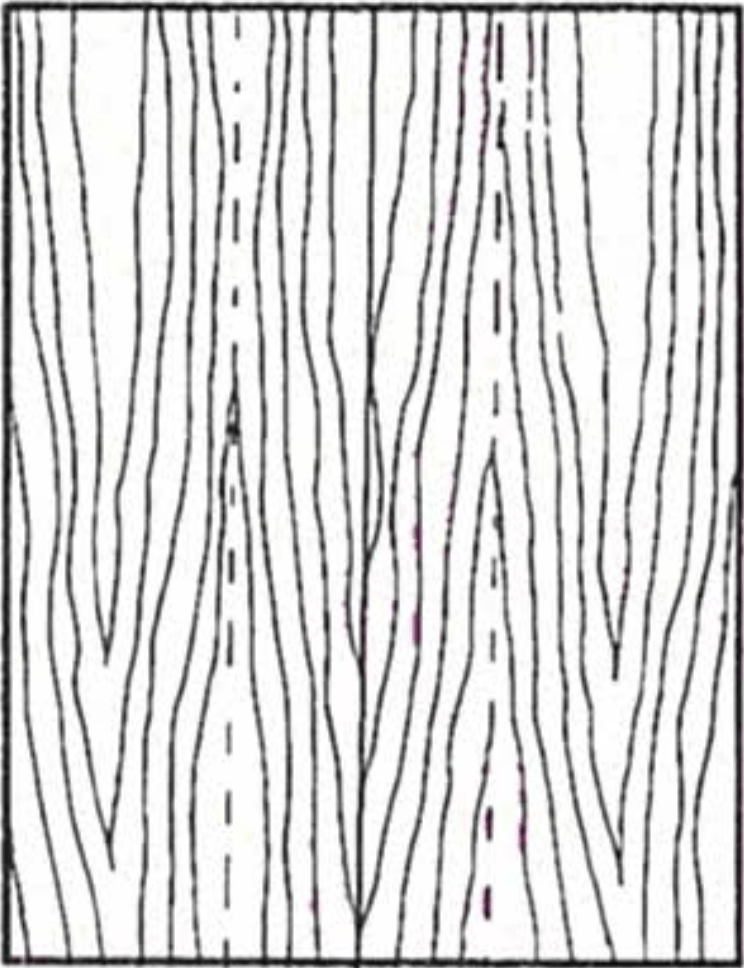

Slip Match

Slip matching means that veneer leaves in a flitch are “slipped”.

Successive veneer lea ves in a flitch are “slipped” one alongside the other and edge-glued in this manner. The result is a series of grain repeats, but no pairs. The danger with this method derives from the fact that grain patterns are, rarely, perfectly straight. Sometimes a grain pattern “runs off” the edge of the leaf, a series of leaves with this condition could usually make a panel – “look like it is leaning”.

In book matching, the pairs balance each other.

Center Match

Center matching means that each panel face is made with an even number of flitch sheets with a center line appearing at the midpoint of the panel and an eual number of veneer sheets on each side of the center line. The number of leaves on the face is always even, but the widths are not necessarily the same.

Balance Match

Balance matching means that each panel face is made from an odd or even number of flitch sheets. The width of each sheet is the same, balanced within the panel.

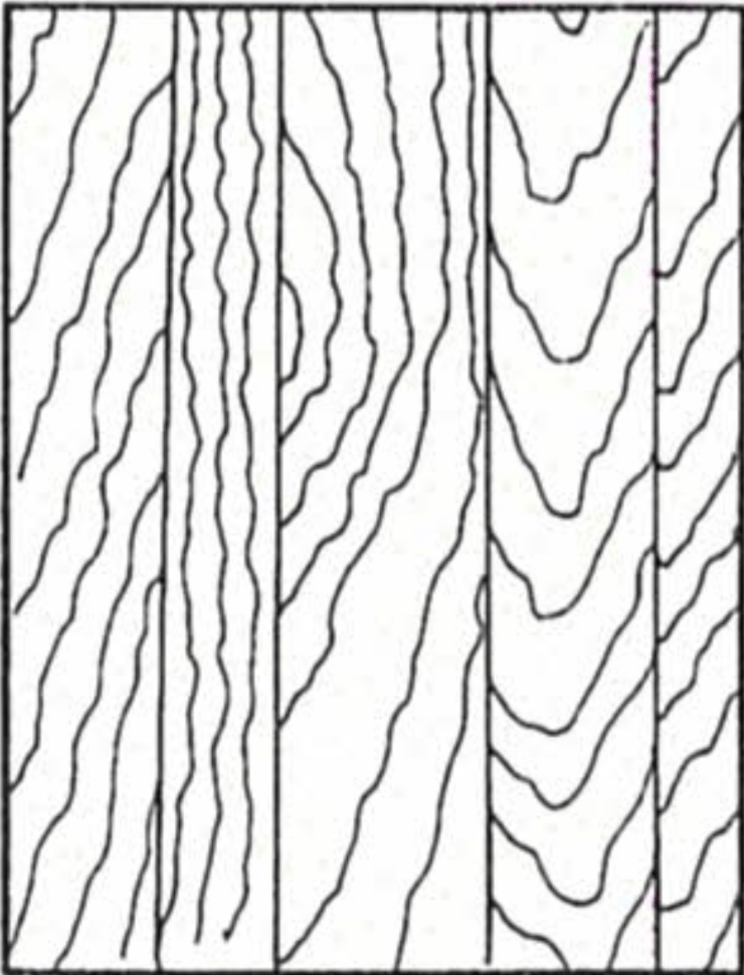

Random Match

Random matching (mismatched) panels have a face made up of specially selected dissimilar (in color and grain) veneer strips of the same species and are generally V-grooved at the joints between strips to simulate lumber planking.

Running Match

Running matching panels are where the face is arranged from as many veneer sheets as necessary for a specified panel width. If a portion of a veneer is left over, it becomes the start of the next panel face.

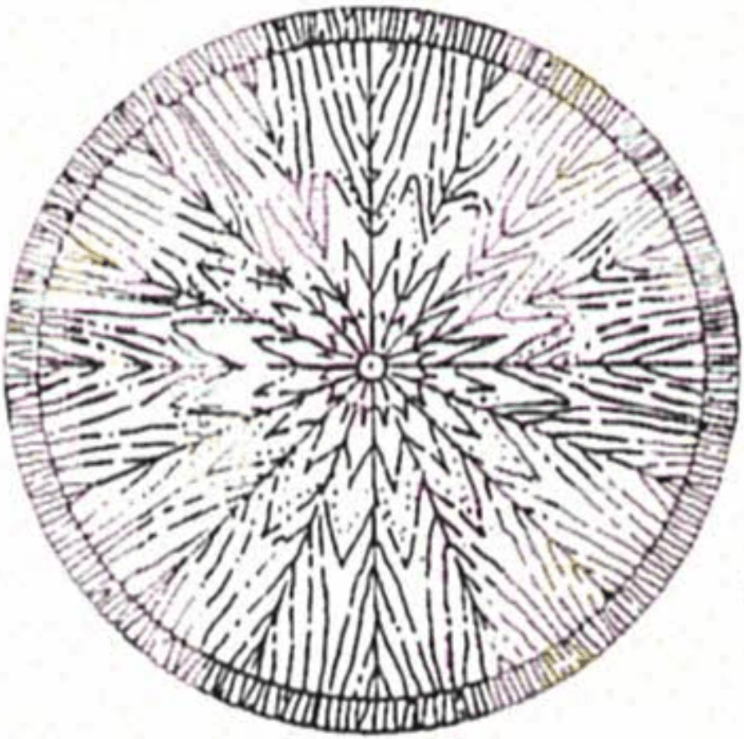

Sunburst Match

Sunburst matching is most commonly done with a crotch or other highly figured wood, and generally on a round, oval, or octagon shaped panel. Successive leaves of veneer are clipped into pie shaped pieces and then book matched. The result will be grain pattern repeats which seem to grow out and expand from a center point.

Blue Print matching is most commonly done with a crotch or other highly figured wood, and generally on a round, oval, or octagon shaped panel. Successive leaves of veneer are clipped into pie shaped pieces and then book matched. The result will be grain pattern repeats which seem to grow out and expand from a center point.

Inlay – Often, the cabinet maker frame sa highly decorative wood grain with a plainer grain to accent it.

Marquetry – Veneer faces of various kinds were made up with small segments of veneer cut into patterns and fitted together. Often many different species and grain patterns are used. These can be made into pictures or just designs. This face is then glued to a substraight as in any plywood manufacture.

These special effects are generally used in furniture manufacturing and can be quite ornate. Many of the most exotic veneers are utilized.

Matching of burls, crotches, stumps – Because of their generally exotic grains, these wood figures need special treatment when being matched into faces. Burls and crotches in particular have a tendancy to be buckled. In the process of making a panel face, the veneer needs to be flattened and patched if needed. They also have a tendency to develop fine hairline splits, so must be carefully handled in further manufacturing. This extra labor and care adds to the expense of using these grains, but the results are usally well worth the cost.

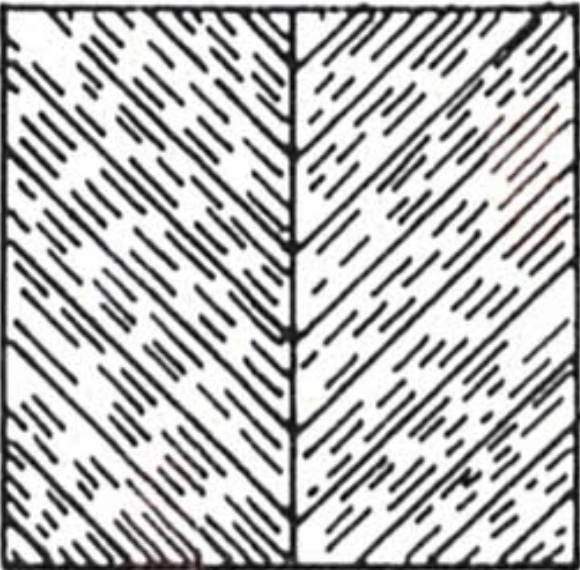

Herringbone – Veneer strips are used and matched to both sides of the center line, at an angle. The resulting appearance is reminiscent of the bones of a fish as they are attached to the back bone.

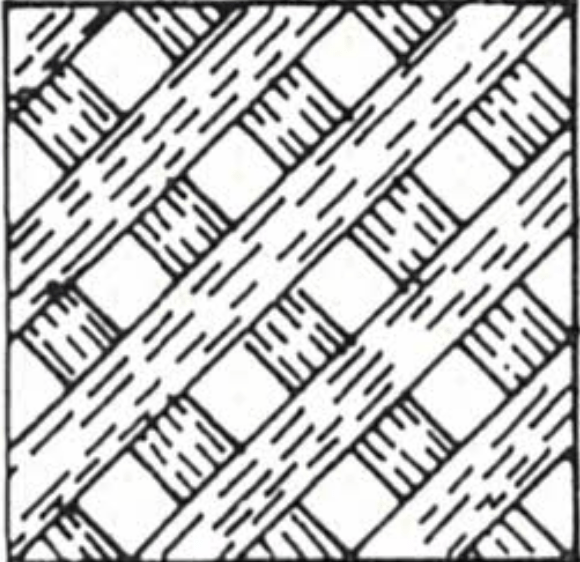

"V" Match Herringbone

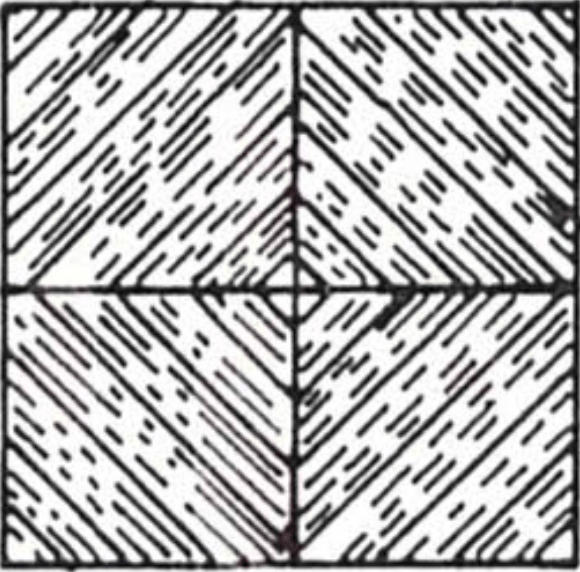

Diamond Match

Reversed Diamond

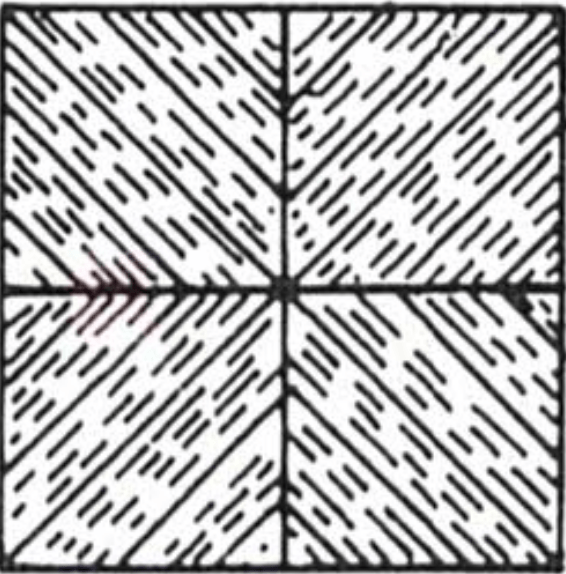

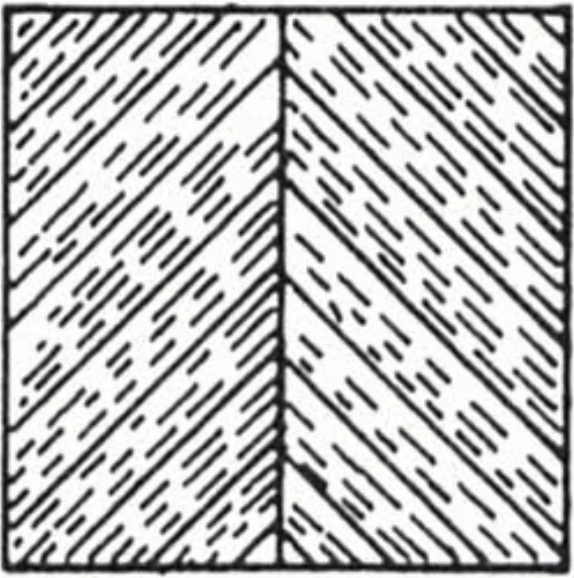

Inverted "V" Match

Basket Weave

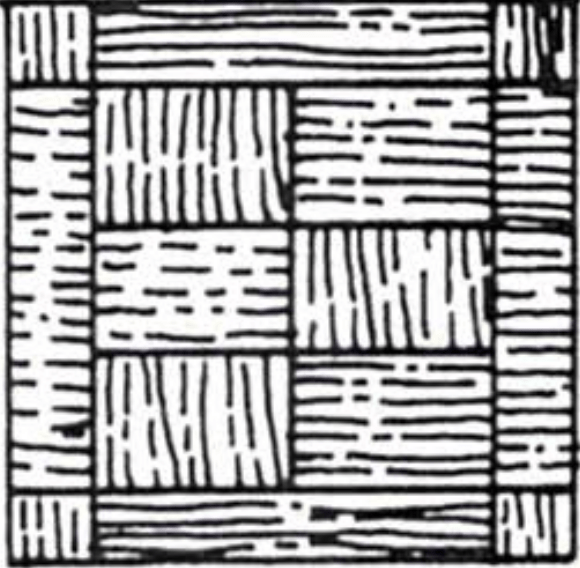

Block Design

Marginal Block

Diamond match – This is generally done with a straight grain veneer. If a rectangle is divided into 4 quadrants, the veneers match at an angle to the quadrant line, and the grain forms a “V” at these lines. The result is a diamond shape formed by the grain directions.

Reversed diamond – This is commonly done with a straight grain veneer, a rectangle is again divided into 4 quadrants. The grain direction is from the center point to the outside edge in each quadrant. The resulting appearance is that of a series of “Vs” formed by the grain match at the joint line pointed in at the center point.

Inverted V Match – See above drawings.

Block Design – See above drawings.

Basket Weave – See above drawings.

Block Marginal – See above drawings.

The above information is a result of our own experience,

combined with excerpts from many publications.