Manufacture & Appearance

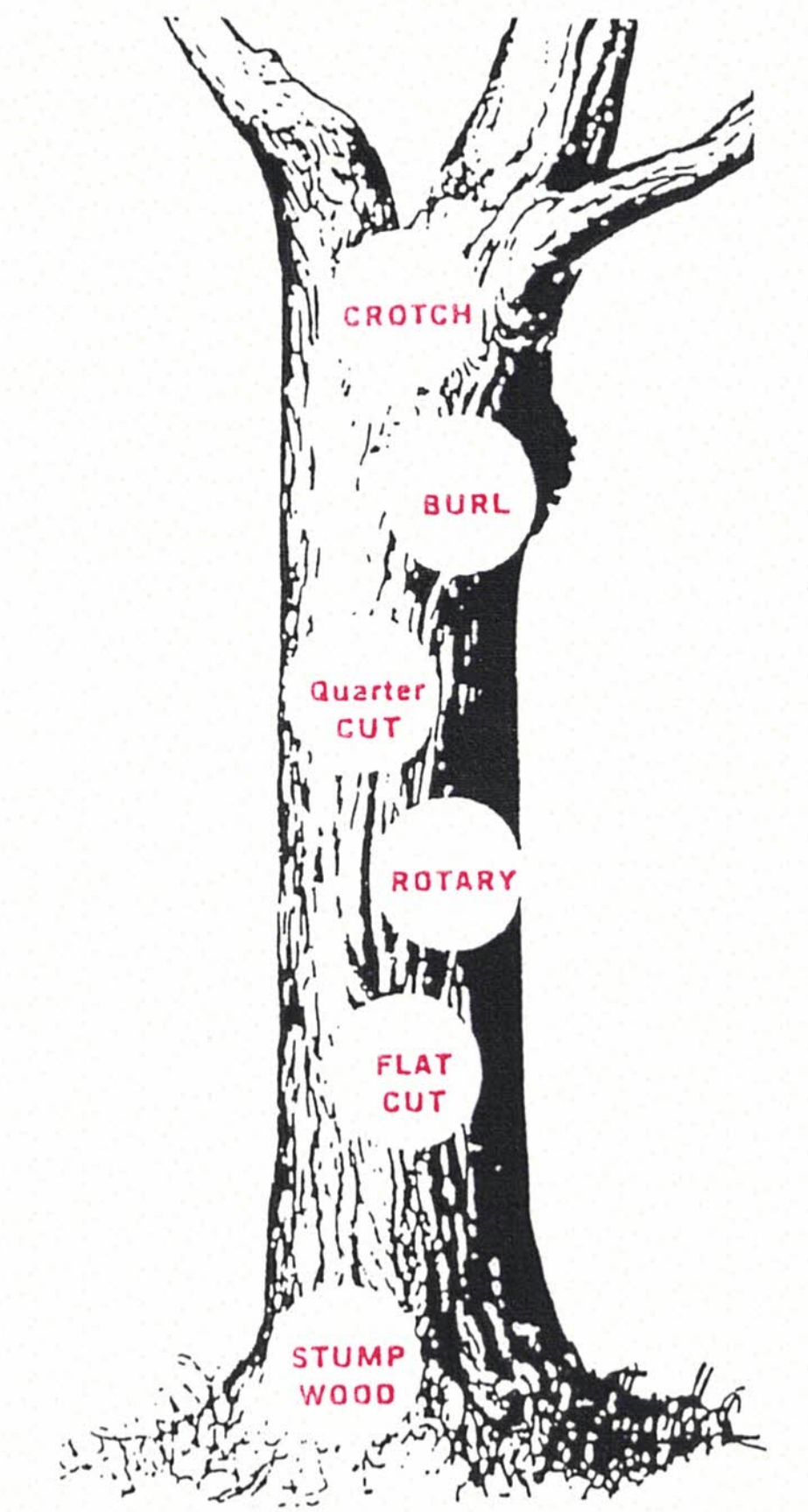

Figure in wood is determined largely by the part of the tree from which the veneer is cut. There are four (4) major sections used for veneers.

1. LONGWOOD – the trunk of the tree, is the part that begins just above the stump and continues to just below the crotch. Most veneers are cut from longwood by quarter, rotary, or flat cutting.

2. CROTCH VENEER – produced from the portion of the tree just below the point where it forks into two limbs. The grain is twisted, creating a variety of flame figures. Often resembling a well formed feather. The outside of the block produces a swirl figure that changes to full crotch flame figure as the cutting approaches the center of the block.

3. STUMP VENEER – proced from the base of the tree. Here the grain pattern is always swirly twisted and often accompanied by cross fire and patches of burl. The sizes are normally small.

4. BURL VENEER – produced from a large, wartlike growth on the trunk of the tree. The grain pattern typically resembles a series of eyes laid side by side. Obviously the veneers leaf sizes are enerally small and additionally are defective. While producing beautiful patterns, Burl veneer is difficult to work with.

Veneering goes back to the early days of the Egyptians, about 3,500 years ago. Down through the years and cultures veneering has enriched furniture and architectural interiors with sheets of rare and beautiful woods bonded ot other plain, sturdy wood based substraights to form a panel.

The art of veneering is simply shaving a thin slice of wood from a log, rather than sawing a heavy board. The original veneering equipment was undoubtedly a crude saw. In fact, some veneer saws are still in use but most have been replaced by knives. Use of a knife elimates teh waste which a saw produces and increases the “yield” of a log. Today this is import both in terms of economics and conservation.

In the fancy veneer industry, logs are produced and manufactured individually. The resulting veneer is sold on an individual basis with the criteria being quality and esthetics.

There are veneers from hardwoods, whcih are generally considered to be broad leaved tree species, and softwoods, which are the needle bearers. There are estimated to be some 90,000 different species under the broad heading of “HARDWOODS”. Of these, only about 100 have ever beenused economically in the fancy veneer industry.