Types of Veneer Manufacturing

Rotary Peeling

How It’s Manufactured

Appearance

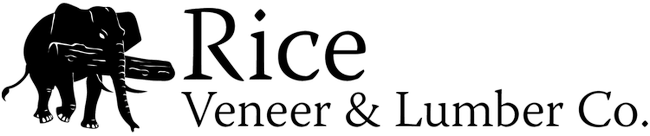

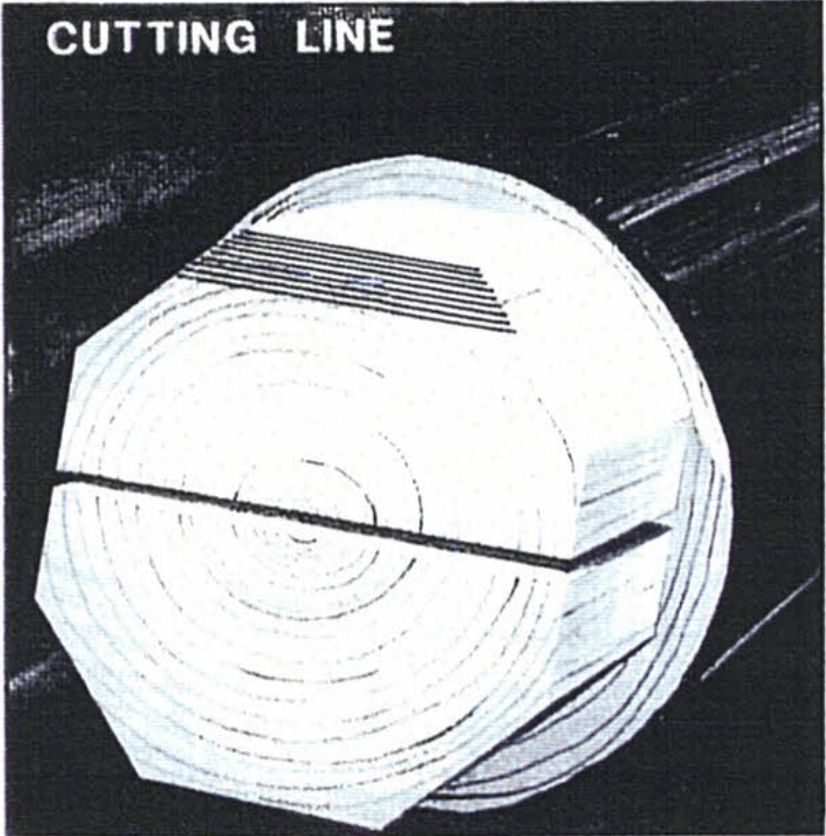

Rotary Peeling

The log is turned in a circular motion against a knife peeling off a continuous thin sheet of wood veneer (like unrolling wrapping paper), the most economical method of producing veneer, resulting in the highest yield. The grain is inconsistent and leaves are most difficult to match. This type of veneer is best suited for paint grade or utility surfaces.

Half Round Slicing

How It’s Manufactured

Appearance

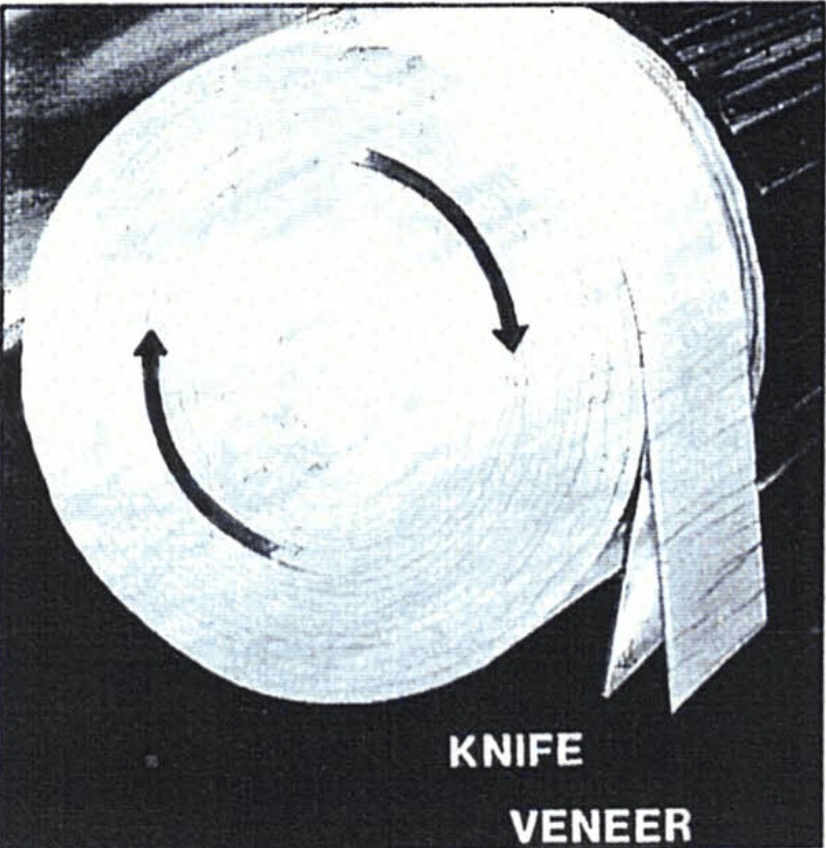

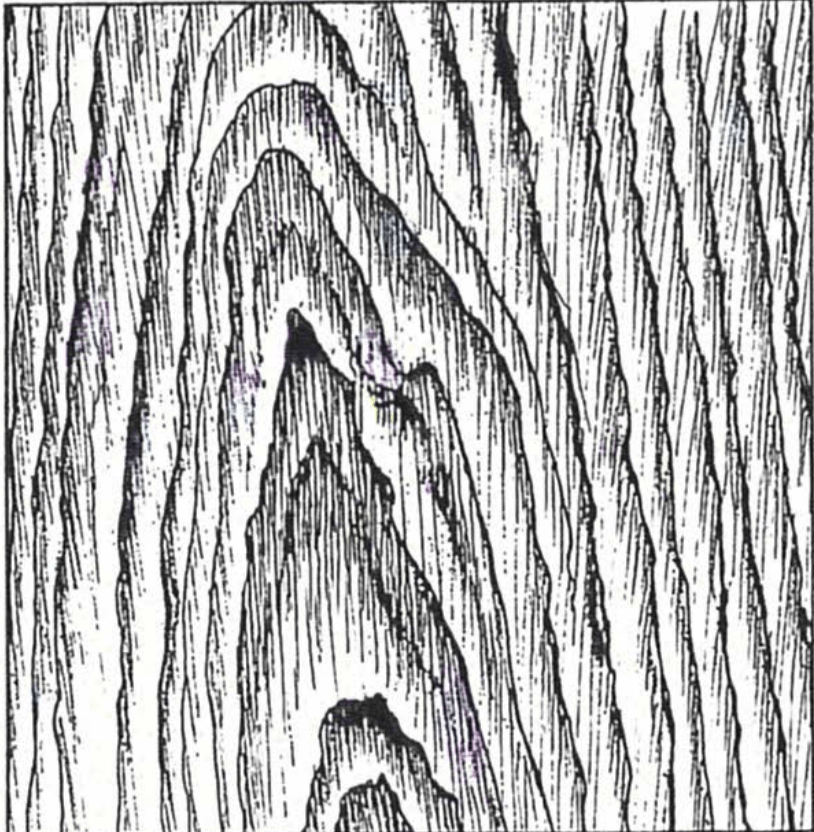

Half Round Slicing

Similar to rotary peeling, also producing a high veneer yield. Used primarily to add width to narrow stocks by increasing the plane of cut. Also used to enhance a particularly wild grain pattern. Matching is possible because the leaves can be kept in sequence. Half round cutting may be used to achieve “flat cut” veneer appearance.

Flat Cut

How It’s Manufactured

Appearance

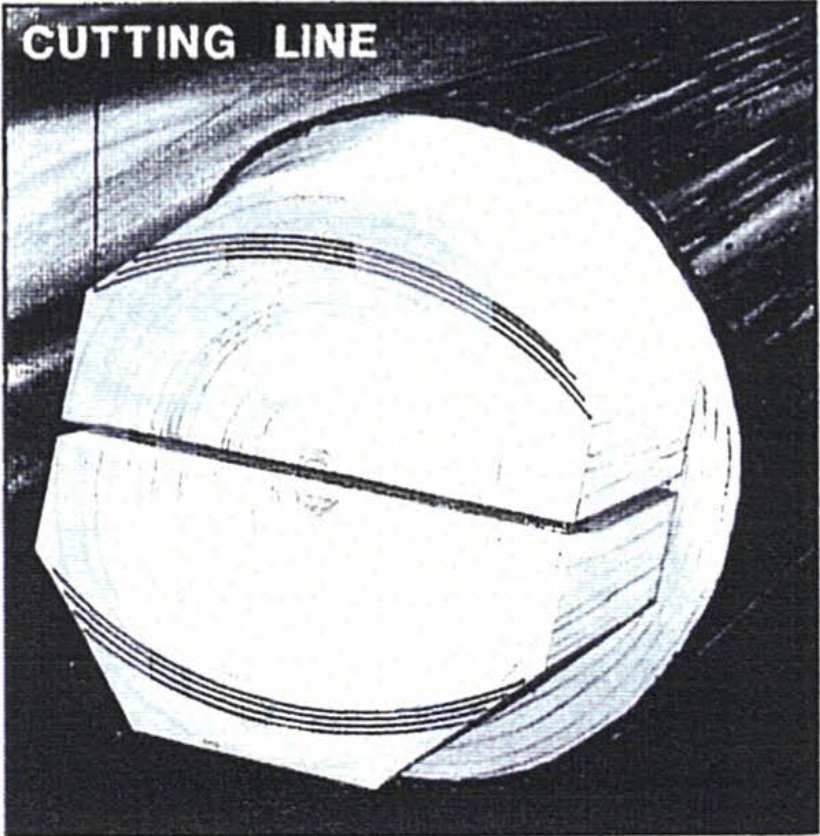

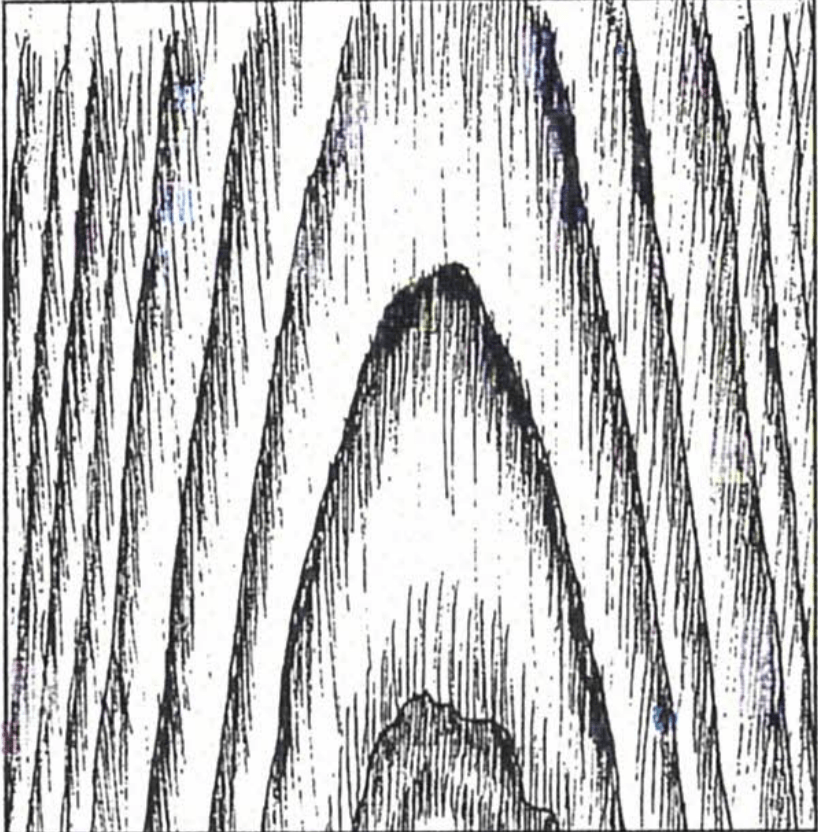

Flat Cut

Also called PLAIN SLICING, is the most common method of veneer manufacturing, producing a grain pattern known as cathedral. Because each leaf in the flitch is similar, a consistent and even matching pattern is possible. Flat cut veneer is ideally suited for wall panels and furniture.

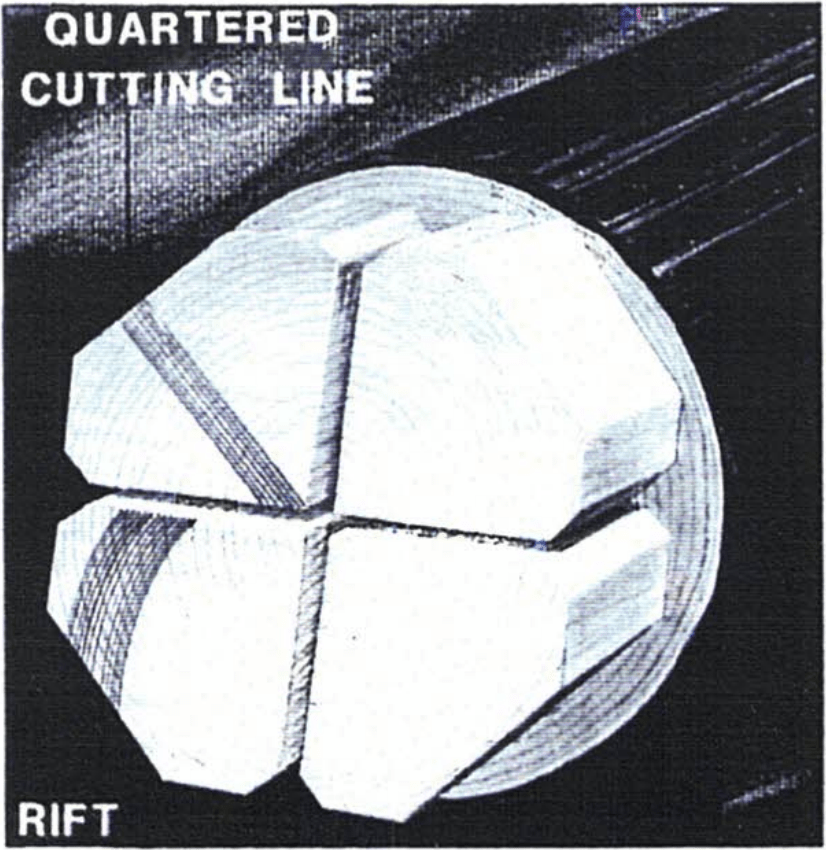

Quarter Slicing

How It’s Manufactured

Appearance

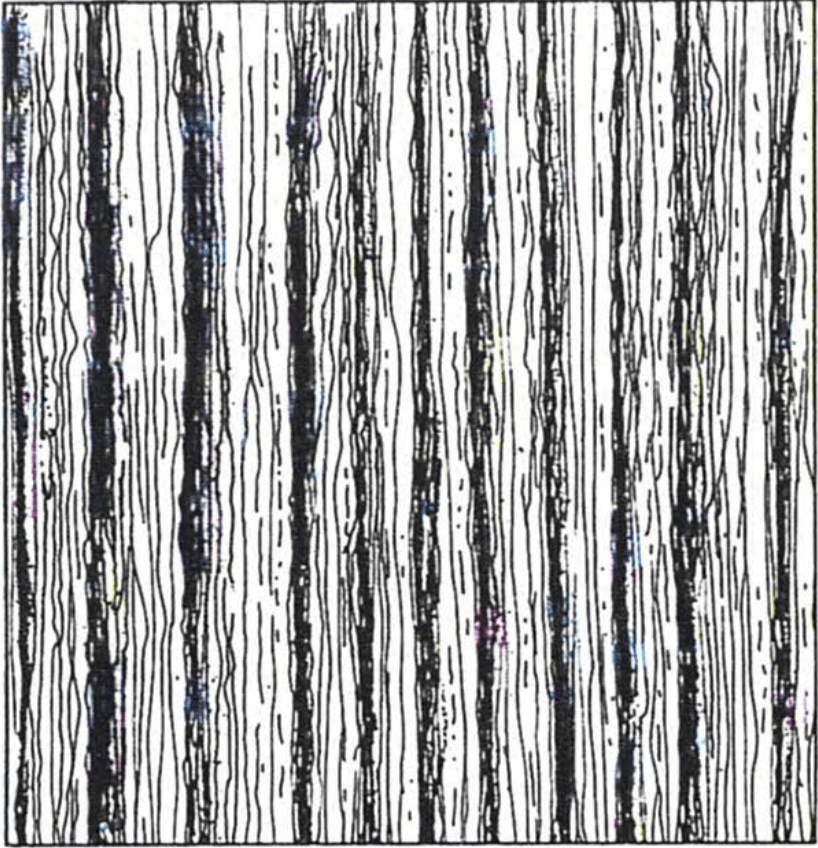

Quarter Slicing

This cut requires the largest diameter logs and produces straight grained veneers. The quarter slicing of oak can result in the appearance of flake.

Rift Cut

Produced by cutting at a slight angle to the radial to produce a quartered appearance without excessive ray flake. The Rift cut method commonly used for Oak, can only be used on sizable logs. Rift Cut veneer can easily be sequenced and matched.